Press

Media Mentions & Press Kit

Media Contact

Ollie Lion | Head of Sales | 01394 420 800 | ollie.lion@rockford.co.uk

Awards

2018

Rockford Receives SC21 Silver 3-Year Award

2017

Rockford Components Business Success Secures Best Practice Award and Creates 100 New Jobs

2015

Rockford Receives Silver Award for the Defence Employer Recognition Scheme

2014

Rockford is Designated as Sharing in Growth Beneficiary

2013

Rockford Receives SC21 Bronze Award

See our full list of Certifications and Accreditations for more relevant information.

Press Highlights

Runway Girl

Electrified foam composite structure has tray table application

Aerospace Manufacturing

Rockford’s ‘electrification of composites’ unveiled at AIX

Composites in Manufacturing

Rockford’s ‘electrification of composites’ unveiled at AIX

The Manufacturer

Rockford Components achieves 160+% export growth

Sharing in Growth

Aerospace Ccompanies On Sharing In Growth Demonstrate Exceptional Export Growth

Sharing in Growth

SME Export Track 100

Sharing in Growth

Rockford Wins Multi-Million Pound Contract for Aircraft Panels

Sharing in Growth

Sharing In Growth: Case Study: Rockford

Engineering Capacity

Multi-million-pound aircraft panel contract

Zenoot

Rockford Wins Multi-Million Pound Contract for Aircraft Panels

CIE Magazine

Rockford Wins Multi-Million Pound Contract for Aircraft Panels

Manufacturing Management

Rockford Ccomponents’ Business Success Secures Best Practice Award

Zenoot

Rockford Components award creates 100 new jobs

The Manufacturer

Wiring provider has been awarded for creating 100 jobs

Sharing in Growth

Rockford Components’ Business Success Secures Inspire Award And Creates New Jobs

Sharing in Growth

One Million Training Hours – But The Clock Is Ticking For Places On SIG Competitiveness Programme

Press Releases

Download Rockford’s recent press releases as PDF below:

Press Release – Passenger Wi-Fi Demands Fibre Optics for Aircraft Interiors October 2018

Press Release – Is it Time for UK Rail to Offer USB Chargers in Every Seat? September 2018

Press Release – Rockford’s Electrification of Composites to be Unveiled at AIX April 2018

Press Release – Rockford Receives SC21 Silver 3-Year Award March 2018

Press Release – Aircraft Panel Contract November 2017

Press Release – Rockford Secures Best Practice Award and Creates 100 New Jobs October 2017

Please see our News page for more blog posts.

Logo

Please click on the image for a higher resolution image to download.

Key Facts

- Established 1978 with 40+ years in business

- We have 280+ employees in the UK

- Three UK facilites: Rendlesham. Worksop, and Salisbury

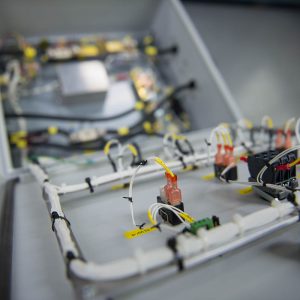

- Over 12m+ harnesses manufactured

History Timeline

- 1978 – Rockford Marks incorporated

- 1983 – Moved to purpose-built premises

- 1984 – Rockford Components incorporated

- 1991 – Purchased quay side mill

- 1992 – Purchased Whitstocks boat yard

- 1997 – Purchased Ipswich electronics

- 1999 – Acquired CLS Wiring (Lucas Rists) and purchased Bradley Electronics Assets

- 2000 – Purchased RAF Bentwaters mission support building (Now Rockford Headquarters)

- 2004 – Labinal facility taken over at Worksop

- 2005 – Acquired Woven Electronics

- 2007 – New facilities purchased in Newcastle Under Lyme

- 2008 – Worksop site purchased from CINCH

- 2009 – CLS/Woven incorporated into Rockford

- 2013 – Kembrey assets purchased & Thales Avionics assets purchased

- 2014 – Rockford-Xellerix UAE

- 2015 – Sharing in Growth investment

- 2017 – System solutions

Key Quotes

We have grown from being a small family firm in 1978 to become the UK’s largest independent provider of wiring, interconnect and system solutions for the aerospace, defence and industrial markets. — Peter Lion, Managing Director

Many of our customers require extra capacity to manage future surges in production and would like a dynamic and flexible electrical partner to meet the demands of predicted aerospace build rates. — Chris Parsonage, Sales & Marketing Director

We’ve gone from being a good British company to being a great international company with over 50% of production exported in 2016. — Steve Hayter, Commercial & Finance Director

Rockford Components was a very deserving winner of the first Sharing in Growth Inspire award last year [2017]. We recognised their determination to drive change, improvement and productivity by harnessing the enthusiasm and skills of their workforce. We are delighted that their efforts are being recognised not only by customers but also by the Sunday Times and Fast Track. — Andy Page, CEO of Sharing in Growth

We have strengthened the leadership around our ambition, increased efficiencies and reduced our manufacturing costs which has given the company a greater competitive position. A reduction in labour costs, along with improved purchasing efficiencies and new marketing material have enabled Rockford to secure some major contracts, which has led to an increased demand on our manufacturing facilities. We have grown our workforce by 30% in 2016 and will continue to grow over the coming years. — Peter Lion, Managing Director

In the past this country has been happy to muddle along. But, if this area wants to be a decent area, with decent jobs and decent pay then there is no choice but to invest in skills and technology. Doing what Rockford is doing now, secures the company and helps secure the country. It helps everyone earn by helping the company make profits. — MP John Mann

Innovation and skills are vital in closing the productivity gap and making businesses more competitive. Companies, like Rockford, who invest in their company and their staff are helping to secure the future of UK manufacturing. — Heather Lawson, Interim Regional Manager with the EEF

We’re really excited to be working on this new project. Rockford is traditionally known for its cables and harnessing products, so this complex electrical panel allows Rockford to showcase its skills in electrical, electronic and mechanical systems and also further highlight our design and integration capabilities. The Rockford team is very proud to be working with a world leading defence aircraft manufacturer on a project of this magnitude. — Chris Parsonage, Sales & Marketing Director

Our weave is extremely flat, highly flexible and strong enough for very demanding applications, such as motorsport and defence. — Mike Molland, Manager at Rockford’s Salisbury Facility

The composite seat tray is going to be the star of the Aircraft Interiors 2018 show for us, and we are all very excited to be part of the team with Equip’Aero. The mutual support and quality of engineering work done has been fantastic. — Chris Parsonage, Sales & Marketing Director

Equip’Aero’s foam-filled composites are incredibly lightweight – 30% to 40% lighter than a traditional composite structure. To attach cables to honeycomb composites, they tend to drill holes, glue metal postings and then attach fixings and attach cabling to the composite structure. We came up with the idea of embedding cabling inside the composite structure so that it’s completely hidden. It’s cheaper and low-cost to install; aesthetically it is also a little more pleasing. We’ve completely embedded electrical cable inside the composite structure, and it is a USB high-speed cable. So, as well as powering your tablet, you can actually send high-speed video through the [tray table],” Parsonage said.“If you are designing a seat, or a monument, or overhead bins, or LED lighting systems, and you wanted to either lower the costs, or create more space by weaving the cable inside, we’re looking at embedding different types of cables into the composite structure. — Chris Parsonage, Sales & Marketing Director

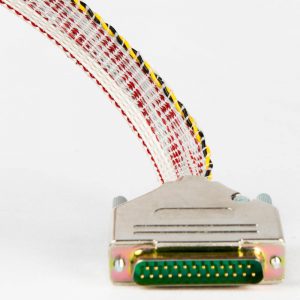

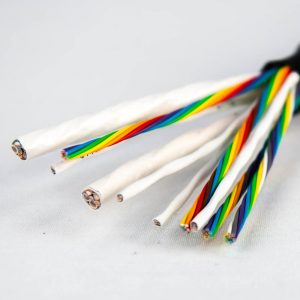

Rockford also weaves cables into fabric, which allows us to deliver completely flat high-capacity cable. We can take a fiberoptic cable, a high-speed cable, a signal cable and maybe a power cable and weave them into a completely flat profile. We can either embed that within the composite or we can weave the Kevlar thread or yarn into a completely flat cable. We can take 20 round cables and make them into a completely flat fabric, and use Velcro to fix it in place. — Chris Parsonage, Sales & Marketing Director

Media Images

Please click on the image you like for a higher resolution image to download.

Please see our Brochures page for more relevant information.